Imagine you have a colander to strain pasta. Over time, bits of food and debris can accumulate in the holes, making it harder for water to drain.

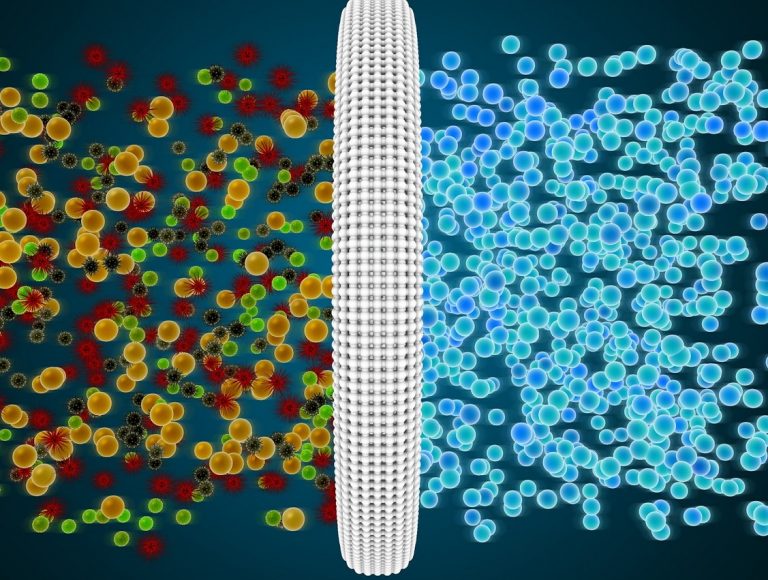

That’s how membrane fouling works. It occurs when unwanted materials deposit on the membrane surface or within its pores, hindering the flow of permeates (the filtered liquid). This can significantly impact your filtration process.

Chemical Cleaning for Stubborn Foulants

When physical cleaning methods fall short, chemical cleaning might be necessary. Here’s where reverse osmosis membrane cleaning comes in. Specific cleaning solutions are used to target and remove accumulated foulants on the membrane surface. However, chemical cleaning should be used judiciously, as harsh chemicals can damage the membrane if not used correctly.

Types of Membrane Fouling

Membrane fouling presents a diverse range of challenges depending on the specific contaminant. Here’s a closer look at the most common types:

Colloidal/Particulate Fouling

Microscopic particles like clay, silt, and metal oxides get lodged on the membrane surface or within its spacers, hindering flow.

Organic Fouling

Dissolved organic matter, such as humic substances and proteins, can adhere to the membrane, forming a dense layer that impedes filtration.

Microbial Fouling

Bacteria, algae, and other microorganisms can thrive on the membrane surface, forming a slimy biofilm that reduces permeability.

Mineral Scaling

Dissolved salts like calcium carbonate can precipitate on the membrane surface, blocking pores and reducing efficiency.

These are the main types of membrane fouling. By identifying the dominant foulants, you can tailor your pretreatment processes, membrane selection, and cleaning procedures for optimal performance.

How Does Fouling Happen?

Membrane fouling unfolds like a silent thief stealing a membrane’s efficiency. Here’s a closer look at the four distinct stages:

Attachment

Foulants, microscopic contaminants like colloids, organics, or microbes, approach the membrane surface due to diffusion, convection, and electrostatic interactions.

Deposition

Once in close proximity, foulants adhere to the membrane surface through various mechanisms, including Van der Waals forces and bridging.

Compaction

As filtration progresses, the deposited layer experiences pressure from the permeate flow. This pressure compacts the layer, making it denser and more restrictive for permeate flow.

Biofilm Formation

In some cases, microbial foulants like bacteria can multiply on the deposited layer. This creates a slimy biofilm that further hinders filtration

Understanding these stages is crucial for developing effective strategies to prevent and mitigate membrane fouling.

The Nasty Effects of Fouling

Membrane fouling disrupts a delicately balanced system, leading to a cascade of negative consequences that can impact not only the efficiency of your filtration process but also your bottom line. Here’s a closer look at the domino effect of fouling:

Reduced Permeate Flux

The most immediate impact is a decline in permeate production. This translates to less treated water or product for a given amount of processing time. Imagine a factory struggling to meet production quotas due to clogged filters.

Increased Transmembrane Pressure (TMP)

As the membrane pores become blocked, more pressure is required to maintain the desired flow rate. This translates to higher energy consumption, lowering operational costs.

Decreased Membrane Lifespan

Fouling can take a toll on the physical structure of the membrane. The constant pressure exerted by foulants and the use of harsh cleaning chemicals can degrade the membrane material. This translates to additional expenses for purchasing and installing new membranes.

Membrane fouling is a multifaceted problem with far-reaching consequences. By understanding these negative impacts, you can prioritize preventative measures and cleaning strategies to ensure optimal membrane performance and system efficiency.

Strategies to Combat Fouling

Fouling prevention is crucial for maintaining optimal membrane performance and reducing operational costs. Here are some key strategies to consider:

Pretreatment

The first line of defense. Implementing pretreatment steps like coagulation, flocculation, sedimentation, and filtration significantly reduces the concentration of potential foulants in the feed water before it reaches the membrane. This minimizes the load on the membrane and extends its lifespan.

Membrane Selection

Not all membranes are created equal. Selecting a membrane with the appropriate pore size, surface properties, and resistance to specific foulants can significantly impact fouling behavior.

For instance, membranes with a larger pore size might be suitable for feed water with high levels of suspended solids. In contrast, tighter pore size membranes might be preferable for applications requiring high purity permeate.

Backwashing

Backwashing involves periodically reversing the flow direction of the feed water. This can dislodge loosely attached foulants from the membrane surface, preventing them from accumulating and forming a more stubborn layer.

The frequency and duration of backwashing cycles should be determined based on the specific feed water characteristics and membrane fouling propensity.

With these strategies, you can significantly reduce the risk and severity of membrane fouling.

Final Thoughts

Membrane fouling can be a headache, but it doesn’t have to be a constant worry. By understanding the causes and implementing these prevention techniques, you can keep your membranes functioning smoothly for years to come. Don’t wait until filtration slows to a trickle – take charge and put a stop to fouling today!