One of the biggest concerns of manufacturers today is how to balance demand with product quality. With so many new and existing markets that they need to cater to, it becomes critical to find a manufacturing process that will allow companies to produce the amount needed and still maintain the quality that their customers expect.

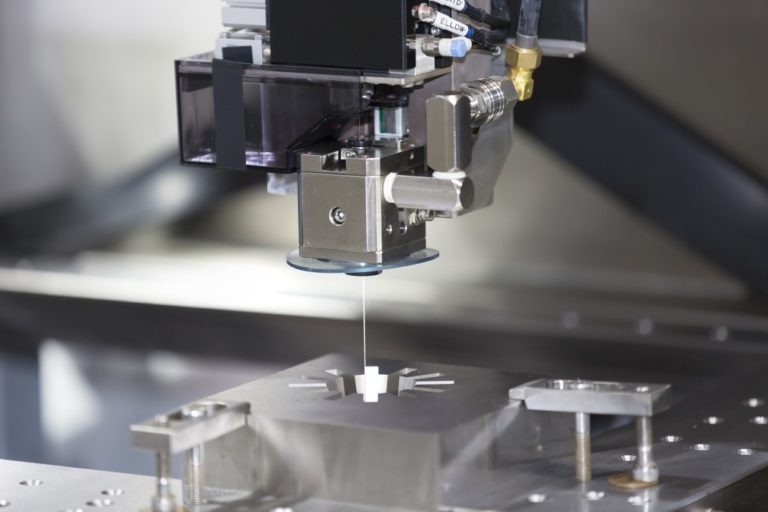

Enter die-casting is one of the most reliable ways to produce a product. Using components such as cartridge heaters and molding systems to create a near-perfect replica of the parts or product needed, it’s rapidly becoming a popular option when it comes to quality and speed of delivery.

However, there are some considerations that a company must take before switching to die casting as a major or primary means of production. Like all production processes, there are some advantages and disadvantages to using die-casting.

Advantages

The biggest advantage of die-casting is the very high dimensional accuracy that you get with the final product. There’s a reason die-cast products are associated with very high standards and levels of craftsmanship: The nature of the production process results in extremely detailed and accurate molded products.

Die-casting can also remove secondary machining procedures that other mass-produced or molded products need. While injection-molded plastics may often need trimming or polishing, die casted products often need no extra treatment once they are out of the mold. Usually, they only need to be painted or packaged before being sent off to shipping.

It’s also extremely efficient; rejected products can be easier to recycle back to their raw forms by simple heating or liquidation. Since metal is one of the most malleable materials, factory losses can be reduced when it comes to the rate of rejected products—a problem that other types of production usually run into.

Disadvantages

The first major barrier that companies will run into is the upfront cost needed to set up a die casting system. Since the equipment is often custom-made for the part that it will eventually produce, it can be more expensive to acquire compared to your usual production equipment.

One of the reasons is because the mold needs to be able to withstand both the material and the high temperatures that die-casting requires. Unlike plastic-based production such as injection molding, die cast molds are heated to extraordinary temperatures to burn away the impurities in the metal and make sure the mold is filled up to capacity.

Another important thing to note is the price of the metal itself. Since die-cast molding exclusively uses metal alloys (though synthetic materials are being developed), the price for the raw material required to buy die cast products can be high. Depending on the application and the final product, several types of metal may also be required.

There is a certain level of production that your company needs to get to before you can seriously consider using die-casting as a means of production. However, with a proper production system in place, it becomes more efficient and you increase the quality of your final product by a large margin.